Improving health and safety in your warehouse is something that can always be improved.

There is no moment where you can say “Ok, that’s the Health & Safety finished, now let’s fix the coffee machine!”.

Improving health and safety is a continuous pursuit to ensure your workers, clients, visitors and products are safe in a dangerous work environment such as a warehouse.

The warehouse industry has the same fatality rate as the farming industry, a statistic that is as shocking as it is unnecessary.

In New Zealand, for the period September 2019 – August 2020, there were 30,612 injuries resulting in more than a week away from work.

Improving health and safety ensure you stay on top of things

Safety barriers

A piece of tape on the floor does not stop people! You need proper safety barriers to protect people and product.

Pedestrian barriers provide obvious segregation between pedestrians and traffic, creating a clearly marked walkway for lower-impact areas.

Forklift barriers are a sturdy stopping force that helps to avoid vehicular collisions. They are designed to segregate work zones and protect your stock and your staff from forklift impact, which is more common than people think.

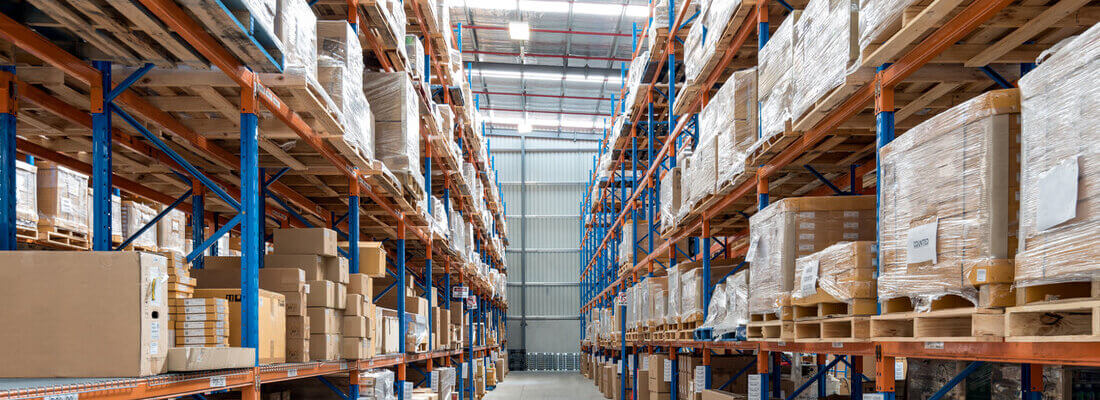

Proper racking

A warehouse is only as good as its shelving, and when it comes to health and safety, old, badly constructed or the wrong type of shelving can be deadly.

From the frames/beams to the width/depth of the shelves, everything must be taken into account.

If you stored pillows for a previous client, but a new one sells bowling balls, then you must update and maintain your shelving to suit your product.

There are plenty of examples out there of racking collapsing, and it’s never pretty.

Personal Protection Equipment

Working in a warehouse tends to be more dangerous than most other jobs, so personal protection equipment is pretty standard.

Issues arise when workers don’t adhere to their use of PPE, whether through familiarity, forgetfulness or simply ignorance.

Employees must wear protective gear at all times when working in a warehouse.

This includes things like steel toecap boots to protect from falling objects or errant forklifts, high-viz jackets, particularly at night, and protective eyewear, especially if projectiles or chemicals are involved.

Keep it clean!

General tidiness is important in a work environment, but when it comes to a warehouse, constant vigilance is necessary to avoid accidents.

If there’s a spill, don’t leave it for someone else to clean, get it mopped up as soon as possible.

If it’s a hazardous material, place a sign to let people know while you sort out the correct equipment to clean it.

Any items lying around should be lifted, not left for a cleaner. Even the smallest thing can be a trip hazard, so don’t take chances with other people’s lives!

Train your employees

The more you talk about safety, the less you’ll hear about accidents.

All new employees should be trained in Health & Safety, but there should also be regular updates for those workers who have been with you for a long time.

Practices change and people forget, so keeping your staff up-to-date on safety regulations and practices is essential. Even a reminder during team meetings once a week keeps people on their toes.

At least one member of your staff should be trained in first aid, and hazardous waste spill kits, emergency medical stations and eye rinsing equipment should be set up in case of emergencies.

As an employer, you should know if your workers are qualified to operate heavy machinery, and only those holding a valid licence for operating forklifts should be using them.

We can help with safety equipment

The number one priority for any business is the welfare of its staff.

Warehouses can be especially dangerous places to work, which is why you need to take every precaution you can to ensure the safety of your employees.

Improving health and safety in your warehouse is also your priority.

Whether your workers drive forklifts or reach trucks, vehicle safety is essential to prevent impact or crush injuries. We have a range of safety barriers and bollards to help protect your products and people.

When it comes to your actual pallet racking, we have everything you need to keep your racking contents in place.

Our pallet stop bars protect your staff and your stock by preventing pallets from being pushed off the rack, while our anti-collapse wire mesh protects your staff from falling products.

We also recommend arranging a maintenance and safety audit to make sure everything is in tiptop condition. This service checks out any damage supplies any new components needed and quickly manages the installation, minimising your downtime and giving you invaluable peace of mind.

Contact us today if you have any questions about warehouse safety or pallet racking audits. Our friendly and knowledgeable staff will be happy to help in any way they can.

Pallet Racking Solutions designs, supplies and installs quality pallet racking and warehouse storage solutions, New Zealand wide. Follow our blog for the latest innovations, new tech, safety and compliance, case studies and in-depth explanations of our solutions.